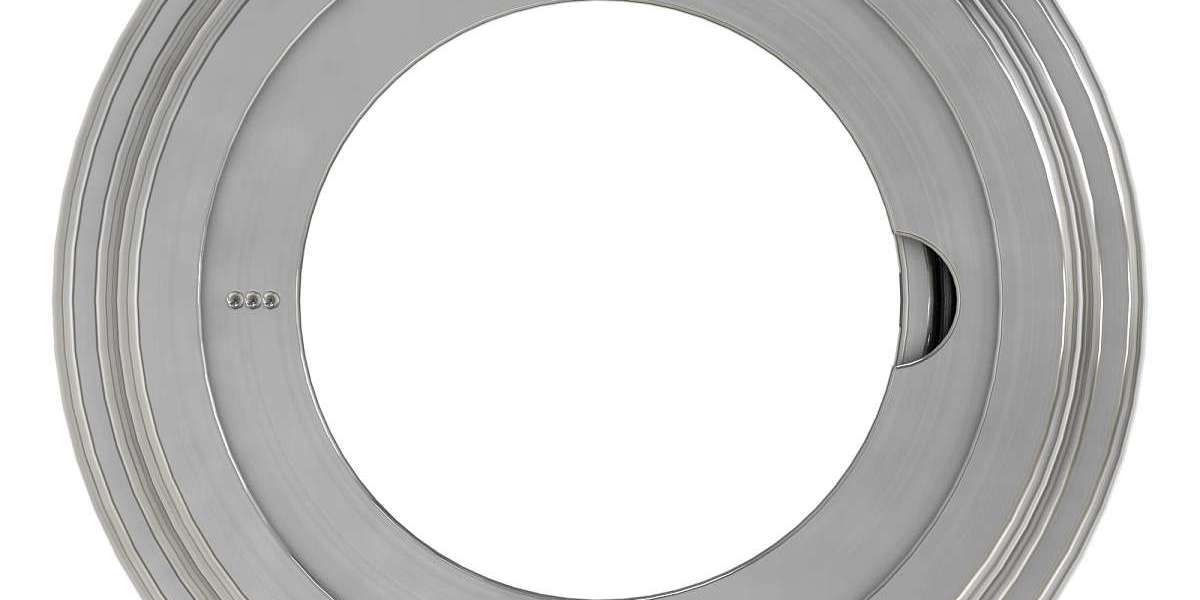

In industrial operations, even the smallest component can determine the difference between continuous productivity and costly downtime. One such critical component is the AH229175 bearing, designed for high-performance mechanical systems that demand precision, strength, and durability.

Whether in heavy machinery, turbines, or conveyor systems, the AH229175 bearing ensures reliable rotation, reduces friction, and supports long-term operational stability. When efficiency and safety are your top priorities, investing in a premium-quality bearing like AH229175 is the smart choice for consistent results.

Understanding the AH229175 Bearing

The AH229175 is a precision-engineered bearing component commonly used in industrial and mechanical applications where load capacity and rotational accuracy are crucial. It is built to handle high radial and axial loads, ensuring smooth and stable performance even under extreme working conditions.

This model is typically used in roller bearing assemblies, drive shafts, and rotating equipment that operate under heavy-duty pressures. Thanks to its advanced design and superior material quality, it delivers exceptional efficiency and mechanical balance.

Key Features of the AH229175 Bearing

The AH229175 bearing stands out because of its exceptional build and reliability. Here are some key features that make it an industry favorite:

High Load-Bearing Capacity: Engineered to manage heavy radial and thrust loads effectively.

Corrosion Resistance: Surface-treated materials prevent rust and degradation.

Smooth Rotation: Designed to minimize friction and vibration during high-speed motion.

Long Lifespan: Resistant to wear and fatigue, even in continuous operation.

Precision Fit: Ensures proper alignment and easy installation across various systems.

Each feature contributes to the bearing’s ability to perform consistently across a wide range of industrial applications.

Technical Advantages of Using the AH229175

Integrating the AH229175 bearing into your machinery brings several technical advantages:

Reduced Maintenance: Its durable design minimizes downtime caused by wear and tear.

Improved Energy Efficiency: Low friction results in less heat generation and power loss.

Enhanced Operational Stability: Consistent load support ensures balanced system performance.

Extended Equipment Life: Protects other mechanical components from stress and misalignment.

Vibration Control: Smooth operation helps maintain system precision.

By choosing a reliable bearing like the AH229175, industries can achieve greater performance consistency and lower operational costs.

Applications of the AH229175 Bearing

The AH229175 is widely utilized across multiple industrial sectors due to its versatility and performance reliability. Common applications include:

Heavy-Duty Machinery: Construction and mining equipment.

Power Transmission Systems: Motors, turbines, and gear assemblies.

Automotive and Transport Equipment: Axles and drive systems.

Agricultural Machinery: Tractors and harvesting equipment.

Industrial Pumps and Compressors: Ensures stable rotation and seal protection.

Its robust design and adaptable dimensions make it suitable for use in any environment that requires precision under pressure.

Why Choose NMR Bearing for AH229175 Bearings

When it comes to mechanical performance and quality assurance, NMR Bearing is a trusted name in the global bearing industry. The AH229175 bearing from NMR is manufactured under strict quality control standards to ensure precision, reliability, and longevity.

Here’s what makes NMR a preferred supplier:

High-Grade Materials: Bearings are produced using advanced alloy steel and heat-treated metals.

Global Manufacturing Standards: ISO-certified production ensures superior quality.

Innovation and Technology: CNC machining and precision grinding enhance accuracy.

After-Sales Support: Expert guidance for installation, maintenance, and compatibility.

Cost-Effective Solutions: Durable products that lower maintenance expenses.

With NMR Bearing, customers get a combination of quality, affordability, and technical expertise.

Performance Benefits in Industrial Operations

Choosing the AH229175 bearing means investing in long-term reliability. Its superior construction helps minimize wear, even under high load cycles, reducing unplanned maintenance costs.

For industries where uptime is critical, NMR’s AH229175 bearing ensures smoother performance, better energy efficiency, and longer equipment life—offering a measurable improvement in productivity.

The bearing’s versatility allows it to be used in multiple mechanical assemblies without modification, simplifying procurement and maintenance processes for large-scale operations.

Maintenance and Care Tips for Extended Bearing Life

Even premium bearings like AH229175 require proper care to achieve optimal performance. Follow these essential maintenance practices:

Regular Lubrication: Use the right grade of lubricant to reduce wear and overheating.

Proper Installation: Ensure alignment accuracy during assembly to prevent imbalance.

Routine Inspection: Check for unusual noise, vibration, or temperature fluctuations.

Avoid Overloading: Operate within recommended speed and load limits.

Clean Environment: Keep the bearing area free of dust, debris, and moisture.

These practices can significantly enhance the bearing’s lifespan and maintain optimal efficiency.

Conclusion

Reliability, precision, and durability — these are the hallmarks of the AH229175 bearing from NMR Bearing. Designed for demanding industrial applications, this bearing delivers consistent results under high-pressure environments while minimizing energy loss and mechanical wear.

If you’re looking to improve your equipment’s stability and reduce maintenance costs, upgrading to the AH229175 bearing is the right move. Explore the complete range of industrial-grade bearings at NMR Bearing and experience engineering excellence built to last.