Procurement Resource, a global leader in procurement intelligence and industrial cost analysis, proudly presents its latest Sulfinpyrazone Production Cost Report. Designed to support manufacturers, investors, and entrepreneurs, this report provides a thorough breakdown of the costs, processes, market dynamics, and financial feasibility associated with sulfinpyrazone production. It serves as a critical resource for anyone looking to enter or expand in the pharmaceutical intermediates manufacturing sector.

Sulfinpyrazone: An Important Pharmaceutical Compound

Sulfinpyrazone is a uricosuric agent primarily used to treat gout and hyperuricemia by increasing the excretion of uric acid in the urine. As a key drug in managing gout-related disorders, sulfinpyrazone holds significant market value in the pharmaceutical industry.

Besides its medicinal applications, sulfinpyrazone serves as an important intermediate in the synthesis of other pharmaceutical compounds. With the increasing global incidence of gout due to lifestyle changes and aging populations, demand for sulfinpyrazone continues to rise, particularly in developed and emerging markets.

Why the Sulfinpyrazone Production Cost Report Matters

Understanding the production cost of sulfinpyrazone is critical for pharmaceutical companies, contract manufacturers, and investors planning production units or expanding existing capacities. The report covers:

- Detailed cost structures

- Raw material sourcing and pricing

- Manufacturing processes and technology requirements

- Capital and operational expenditures

- Regulatory and quality control considerations

- Market demand and pricing analysis

These insights allow stakeholders to optimize production strategies, improve profitability, and minimize financial risks.

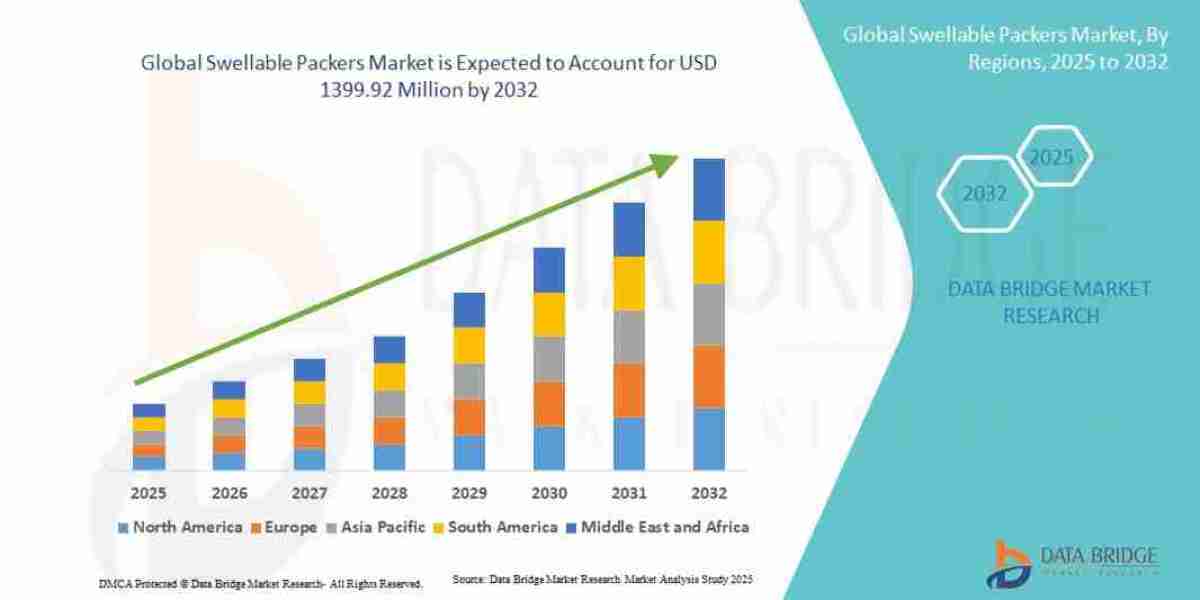

Market Overview: Global Demand and Regional Dynamics

Sulfinpyrazone demand closely follows the pharmaceutical markets of North America, Europe, and Asia-Pacific. Countries with growing elderly populations, such as Japan and parts of Europe, have stable consumption levels, while emerging markets in Asia show increasing demand.

The report analyzes:

- Regional consumption patterns and forecasts

- Impact of patent expirations and generic drug penetration

- Regulatory frameworks affecting production and pricing

- Competitive landscape of key sulfinpyrazone manufacturers

Raw Material and Pricing Analysis

The production of sulfinpyrazone requires several key raw materials, including:

- Pyrazolidine derivatives

- Sulfinic acids or sulfinyl reagents

- Organic solvents (e.g., ethanol, toluene)

- Catalysts and reagents for chemical synthesis

The report tracks price trends and supply stability for these inputs. Volatility in raw material prices, especially specialty chemicals and solvents, can impact overall production costs significantly. Procurement Resource provides detailed supplier benchmarking and risk mitigation strategies for raw material procurement.

Technical Process Overview: Step-by-Step

Sulfinpyrazone synthesis involves multi-step organic chemical reactions, including:

- Preparation of pyrazolidinedione intermediates

- Sulfinylation reactions to introduce the sulfinyl group

- Purification and crystallization to isolate pharmaceutical-grade sulfinpyrazone

- Drying and milling to achieve the required particle size for formulation

The report details reaction conditions, catalysts used, temperature and pressure controls, yield optimization, and waste management. It highlights common challenges like controlling impurities and scaling from lab to industrial batch sizes.

Equipment and Infrastructure Requirements

Depending on plant capacity and automation level, the following equipment is essential:

- Reactors for batch synthesis, often glass-lined or stainless steel to resist corrosion

- Distillation and solvent recovery units

- Filtration and centrifugation systems

- Dryers (tray dryers or spray dryers)

- Crystallizers and milling machines

- Quality control and analytical instrumentation (HPLC, GC-MS)

Infrastructure must include chemical storage facilities, solvent handling safety systems, ventilation, and effluent treatment plants to comply with environmental standards.

Utility and Manpower Needs

Utility Consumption

Sulfinpyrazone manufacturing involves energy-intensive chemical reactions and solvent recovery. Utilities required include:

- Electricity for reactors, pumps, and dryers

- Steam or heating sources for reaction control

- Process water for cooling and cleaning

- Compressed air for pneumatic systems

The report provides detailed consumption estimates and associated costs per production unit.

Workforce Requirements

A skilled workforce is critical, including:

- Organic chemists and chemical engineers

- Quality assurance and regulatory compliance experts

- Plant operators and maintenance technicians

- Health, safety, and environmental (HSE) officers

The report offers a manpower planning guide tailored to plant size and automation levels.

Financial and Economic Assessment

Capital Investment Overview

Capital costs include:

- Land acquisition and factory setup

- Machinery and equipment procurement

- Installation and commissioning

- Licensing, regulatory compliance, and certification costs

- Contingencies and working capital

The report provides models for small, medium, and large-scale production units, including automation investment trade-offs.

Operating Cost Breakdown

Operating expenses encompass:

- Raw material purchase costs

- Energy and utility bills

- Labor costs

- Maintenance and consumables

- Waste disposal and environmental compliance

- Quality control and packaging

Unit production costs are broken down by batch size and plant capacity, helping manufacturers optimize cost-efficiency.

Profitability and ROI

Based on global market price trends for sulfinpyrazone and projected demand growth, the report includes:

- Gross margin calculations

- Net profit estimates

- Return on investment (ROI) projections over 3, 5, and 7 years

- Sensitivity analysis showing impact of raw material price swings and regulatory changes

Regulatory and Quality Assurance Considerations

Sulfinpyrazone is a regulated pharmaceutical intermediate, so stringent GMP (Good Manufacturing Practice) compliance is mandatory. The report details:

- Quality control protocols (purity, residual solvents, impurity profiling)

- Documentation and batch record maintenance

- Regulatory filings for drug intermediates

- Environmental and safety regulations, including handling of hazardous solvents and reagents

These considerations directly affect production cost due to the need for specialized equipment and processes.

Sustainability and Emerging Industry Trends

Increasing environmental regulations and the drive for greener manufacturing are impacting sulfinpyrazone production:

- Use of solvent recovery and recycling systems to reduce emissions and cost

- Transition to safer, less hazardous reagents

- Waste minimization and byproduct valorization

- Automation and digital monitoring for process optimization

The report evaluates how these trends affect both the cost structure and the competitive landscape.

Growth Opportunities and Market Outlook

The sulfinpyrazone market is poised for growth due to:

- Rising prevalence of gout and related conditions worldwide

- Expansion of generic drug production

- Emerging markets increasing pharmaceutical consumption

- Innovation in drug delivery systems requiring refined intermediates

Procurement Resource’s analysis helps investors identify promising regions and scale strategies.

Why Choose Procurement Resource?

Procurement Resource combines expert domain knowledge with data-driven analysis to deliver:

- Detailed production cost models

- Market and raw material price tracking

- Risk assessment and supply chain intelligence

- Customized reports for strategic planning

Our reports empower businesses to reduce costs, optimize operations, and enhance profitability.

Get Your Free Sample Report

For detailed insights into sulfinpyrazone production costs and market dynamics, request your free sample report today:

Request Here: https://www.procurementresource.com/production-cost-report-store/sulfinpyrazone/request-sample

Contact Information

Company Name: Procurement Resource

Contact Person: Ashish Sharma (Sales Representative)

Email: sales@procurementresource.com

Location: 30 North Gould Street, Sheridan, WY 82801, USA

Phone:

UK: +44 7537171117

USA: +1 307 363 1045

Asia-Pacific (APAC): +91 1203185500

Connect With Us Online:

https://www.linkedin.com/company/procurement-resource-official/