Procurement Resource, a global leader in procurement intelligence and market research, proudly presents its latest Heavy Aromatic Naphtha Solvent Production Cost Report. Designed to support manufacturers, investors, and entrepreneurs, this report delivers crucial insights into the cost structure, production process, market dynamics, and profitability associated with producing heavy aromatic naphtha solvents.

By offering detailed economic assessments and technical evaluations, the report empowers stakeholders to make informed decisions on setting up or optimizing production facilities for this vital industrial chemical.

Heavy Aromatic Naphtha Solvent: A Versatile Petrochemical Product

Heavy Aromatic Naphtha Solvent (HANS) is a high-boiling, aromatic-rich petroleum fraction derived from catalytic reforming or distillation processes. It is known for its excellent solvency, high flash point, and chemical stability. These properties make it indispensable in industries such as:

- Paints and coatings

- Adhesives

- Rubber processing

- Printing inks

- Agrochemicals and pesticides

- Cleaning and degreasing formulations

Owing to its ability to dissolve a wide range of resins, waxes, and polymers, heavy aromatic naphtha is a preferred solvent for formulations requiring consistent performance under demanding conditions.

In-Depth Production Cost Report for Strategic Decision-Making

The Heavy Aromatic Naphtha Solvent Production Cost Report provides a detailed blueprint for businesses aiming to enter or expand in the solvent manufacturing domain. From raw material sourcing and process design to utility requirements and investment models, the report covers all critical factors necessary for a successful setup.

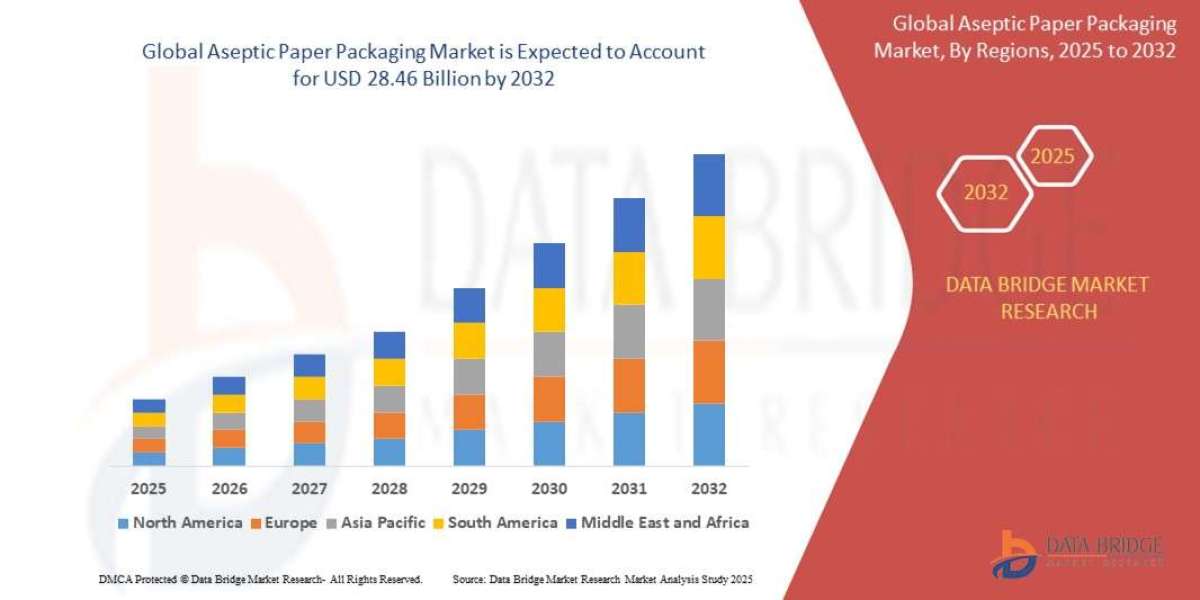

Global Market Trends and Regional Demand Analysis

Market Overview

The demand for heavy aromatic naphtha solvents is closely linked to the health of end-user industries such as construction, automotive, and packaging. Key growth drivers include:

- Expanding infrastructure and construction activity in Asia-Pacific

- Increasing use of specialty coatings and adhesives in manufacturing

- Rising demand for high-performance solvents in industrial cleaning

The report provides a region-wise breakdown of consumption trends, regulatory influences, and import-export dynamics, with a focus on high-demand regions such as China, India, Southeast Asia, Europe, and North America.

Raw Material Overview and Price Volatility

Primary Raw Materials:

- Reformate streams or heavy naphtha fractions

- Crude oil derivatives (from FCC or coker units)

- Additives and stabilizers (if applicable)

Since HANS is typically a by-product or fractionated stream obtained from petroleum refining, its pricing is heavily influenced by:

- Crude oil prices

- Refinery configuration and throughput

- Demand for light vs. heavy aromatics

The report includes an analysis of raw material cost trends, availability, and procurement risks, helping producers manage volatility and secure stable supply chains.

Production Process and Technical Workflow

Process of Heavy Aromatic Naphtha Solvent:

HANS is primarily obtained through one of the following processes:

- Catalytic Reforming and Fractionation

- Reformate rich in aromatics is distilled to separate heavy fractions (typically C9–C11 aromatics).

- Thermal Cracking or FCC Streams Processing

- Aromatic-rich heavy fractions are extracted and refined.

- Solvent Extraction and Purification

- Solvent refining may be employed to improve color, odor, and performance parameters.

Step-by-Step Process:

- Feedstock selection and pre-treatment

- Fractional distillation under atmospheric or vacuum conditions

- Selective hydrogenation or hydrofining (optional)

- Solvent recovery and stabilization

- Blending and quality control

- Packaging and storage

The report outlines process flow diagrams, input-output ratios, and waste management practices, offering a holistic view of plant operations.

Machinery and Equipment Requirements

A modern heavy aromatic solvent plant requires the following key components:

- Distillation columns

- Heat exchangers and condensers

- Feed preheaters and pumps

- Solvent refining systems

- Storage tanks and blending units

- Packaging and drum-filling systems

The report compares technology configurations for semi-automated vs. fully automated systems, tailored to different plant capacities and compliance needs.

Infrastructure and Utility Planning

Plant Layout and Infrastructure Essentials:

- Land area (based on throughput volume)

- Utilities: electricity, steam, nitrogen, and process water

- Effluent treatment and VOC emission control systems

- Safety systems for fire, explosion, and toxic exposure

- Quality control laboratories and logistics zones

Energy consumption is a key operational parameter due to heating and distillation needs. The report provides detailed estimates of power, fuel, and water requirements.

Manpower and Human Resource Requirements

To ensure smooth plant functioning, the report outlines the following staffing structure:

- Chemical engineers and process technicians

- Instrumentation and utility operators

- Quality control analysts

- Logistics and warehouse staff

- EHS and regulatory compliance officers

Labor cost estimations by region and skill level are included to help forecast operating expenses.

Quality Control and Regulatory Compliance

Given the flammability and environmental sensitivity of HANS, strict adherence to regulatory norms is essential. The report discusses compliance with:

- REACH and CLP Regulations (EU)

- OSHA, EPA, and DOT (USA)

- Hazardous waste and air emission controls

- Labeling and transport classifications (UN/IMDG codes)

Quality parameters such as aromatic content, distillation range, flash point, specific gravity, and odor are also detailed, along with required testing protocols.

Financial Analysis: CAPEX and OPEX Insights

Capital Investment Overview:

The report provides capital cost estimates for:

- Land acquisition and site development

- Plant construction and utilities setup

- Equipment and machinery procurement

- Instrumentation and safety systems

- Commissioning and working capital

It offers scalable investment models for small, medium, and large-scale plants.

Operating Cost Breakdown (OPEX):

Recurring cost components include:

- Feedstock procurement and transportation

- Utilities and fuel (steam, electricity, cooling water)

- Labor and administrative expenses

- Maintenance and spare parts

- Packaging and distribution

The report gives a granular cost-per-ton analysis for accurate cost benchmarking and performance tracking.

Profitability Assessment and ROI Forecast

Based on current and projected product pricing, the report delivers:

- Gross margin and EBITDA projections

- Return on investment (ROI) scenarios

- Net present value (NPV) calculations

- Internal rate of return (IRR) models

It also includes best-case and worst-case projections under different pricing and demand assumptions.

Break-Even and Payback Analysis

To evaluate the commercial viability of a production plant, the report includes:

- Break-even volume and revenue calculations

- Fixed vs. variable cost ratios

- Payback period estimations under multiple production scales

This allows investors to measure risk exposure and determine capital recovery timelines.

Sustainability Trends and Emerging Market Shifts

While traditional heavy aromatic solvents are derived from fossil fuels, the market is gradually shifting toward lower-emission and greener solvent solutions. The report highlights trends such as:

- Use of bio-aromatics and renewable feedstocks

- Solvent recovery and reuse in closed-loop systems

- VOC emissions reduction technologies

- Enhanced biodegradability standards

These innovations present new opportunities for differentiation and regulatory incentives in key markets.

Why Partner with Procurement Resource?

Procurement Resource is a trusted partner for global businesses seeking transparent, data-driven insights into chemical production and procurement. The firm delivers:

- Customized production cost models

- Market entry and plant feasibility reports

- Raw material benchmarking and sourcing strategy

- Real-time market pricing and supply chain intelligence

With a multidisciplinary team and proprietary databases, Procurement Resource supports clients in achieving cost efficiency, compliance, and sustainable growth.

Get a Free Sample Report Today

Looking to launch or expand your Heavy Aromatic Naphtha Solvent business? This comprehensive report is your essential guide to financial, operational, and strategic planning.

Request a Free Sample Report: https://www.procurementresource.com/production-cost-report-store/heavy-aromatic-naphtha-solvent/request-sample

About Procurement Resource

Procurement Resource offers leading market intelligence and cost modeling solutions across sectors such as chemicals, agriculture, energy, metals, and food processing. With global clients and proven methodologies, the company delivers actionable insights that drive growth and reduce procurement risk.

Contact Information

Company Name: Procurement Resource

Contact Person: Ashish Sharma (Sales Representative)

Email: sales@procurementresource.com

Location: 30 North Gould Street, Sheridan, WY 82801, USA

Phone:

UK: +44 7537171117

USA: +1 307 363 1045

Asia-Pacific (APAC): +91 1203185500

Connect With Us Online:

https://www.linkedin.com/company/procurement-resource-official/